| Always Mix, Never Worry |

Marcy Petrini

January, 2024

Well, almost never.

For a long time, my go-to-yarn size has been 10/2, starting with mercerized cotton. Below is a scarf that serves as a sampler for twills which also provides some texture.

I could add more textures using a rayon loopy yarn as weft on a 10/2 mercerized cotton as I did in the scarf below.

Eventually Tencel™ became available to weavers. Sometimes it is confused with rayon which includes bamboo, but Tencel™ has its own trademark from a proprietary process which is reportedly more environmentally friendly that the rayon process.

My favorite is 10/2 Tencel™, which sometimes it’s hard to find; 8/2 is more common The scarf below was woven with a 10/2 Tencel™ warp and weft from a Convergence® color scheme.

Tencel™ uses the same yarn system as cotton, 10/2 is the same size for both yarns, so they can be easily combined. Whichever yarn I use depends on what colors I have available. The flexibility is great. The scarf below uses 10/2 Tencel™ warp and 10/2 mercerized cotton weft.

Then one day I was working with 10/2 Tencel™ and looking for a specific color; I picked up a yarn I planned on using, only to realize that it felt a bit different than the others: sure enough, it was 20/2 silk, which is the other yarn I like to use. It turns out that 10/2 cotton and Tencel™ are very similar in size to 20/2 silk, so I had another option for mixing.

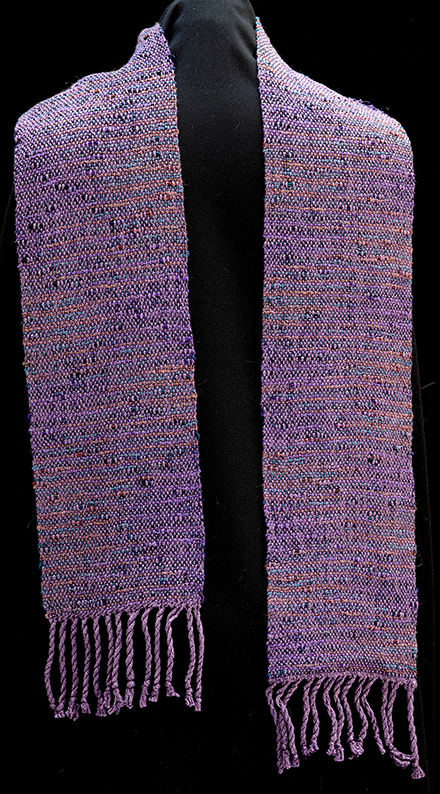

Below is a scarf that uses 20/2 silk for the warp, except for 10/2 rose Tencel™ stripes and then 10/2 Tencel™ for the weft.

Other size yarns can be mixed. Below is a scarf with a warp of 8/2 silk in rust, light brown and light green; I needed a gold, so I used 5/2 mercerized cotton. The warp was sett at 20 epi and the weft was light yellow 8/2 silk.

When warping with yarns that are very different in size, I use a reed in which the largest yarn fits easily. Then I double or triple the other yarns as appropriate. For some rigid heddle looms, reed pieces with different setts work well for this purpose.

When using this approach, it is good to remember that if warp ends are threaded on different shafts, but sleyed together, they will behave as the original size. If threaded together, then they become approximately the size of the combined yarn. For example, if I use two strands of a 10/2 yarn threaded on separate shafts, the yarn will behave as a 10/2. If I thread it together, it behaves close to 5/2. I have seen rigid heddle weavers not realize this difference and end up with a fabric that felt differently that they had anticipated.

I combine synthetic yarns. Here is a scarf for the holidays: 5/2 silk in green and red and “Furreal by Knitting Fever”, a black faux fur. The sett was 10 epi, which brings me to my rule of thumb: if the weft is larger than the warp, open up the sett, as I did here. If the weft is smaller than the warp, sett the warp more closely.

When mixing animal and plant fibers, I am careful to wet finish for the more delicate fiber. Most wools full and shrink a great deal with warm water and agitation. That’s how we full wool on purpose, to make wadmal, for example. Yarns made from Down sheep are less likely to full. (I use the term full because “felt” is the result of fiber, not yarn, binding together).

Below is a scarf with a wool and silk blend for warp and a slubby rayon for weft. Even with cold water weft finishing, there was quite a bit of shrinkage, 15% width-wise and 10% length-wise. In a scarf it doesn’t matter, but if planning a project where a specific amount of fabric is needed, for example for a garment, there is no substitute for sampling.

Next time you want to weave a project with different yarns, plan and finish carefully, it should work, but sample if unsure.

Happy exploring different yarns together!

Marcy